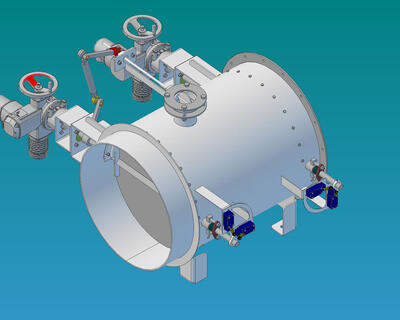

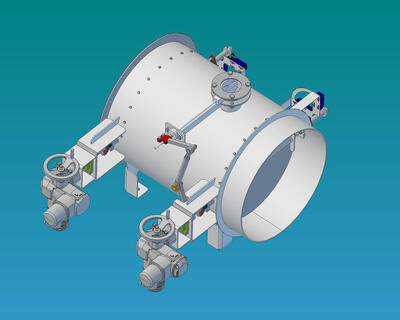

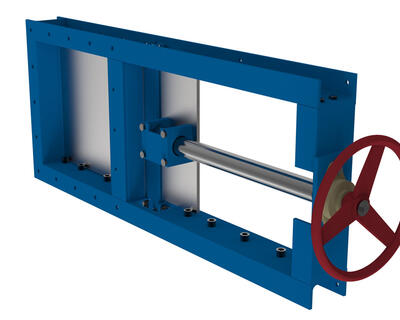

Air and flue gas dampers

We construct and produce air- and flue gas dampers given Your individual technical specification. Our solutions are especially suitable for the following areas:

- ship catalysts

- exhaust fumes of turbines and engines for the drying process of the tile and ceramic Industry as well as in the wood processing and cellulose processing Industry

- energy recuperation plants

- hot gas generators

- thermal reactors

- industrial boilers and thermal power stations with conventional boilers or boiling beds

- shut-off dampers and regulating dampers for heat exchange and for particle separation

- protection of the bag filters leading to the grinding stations

- flue gas conduits of the rotary kiln, circulation to the coolers, circulation to the grinders in the cement industry

- pipes of the furnace and the coke oven battery, heat exchangers, flue gas purification plant, direct reduction process in the steel industry

- thermal post-combustion, flue gas purification plants and energy recuperation from flue gas in the chemical and petrochemical industry

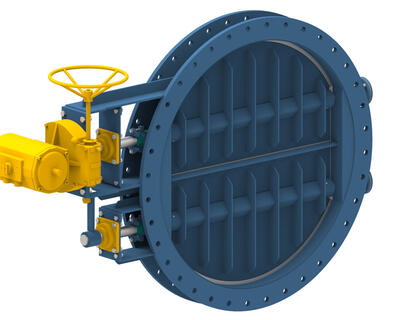

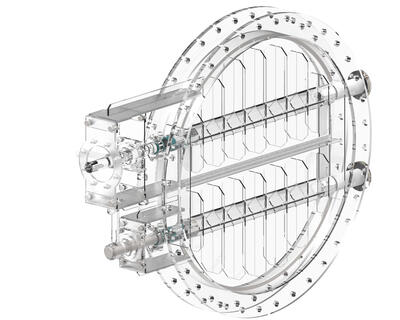

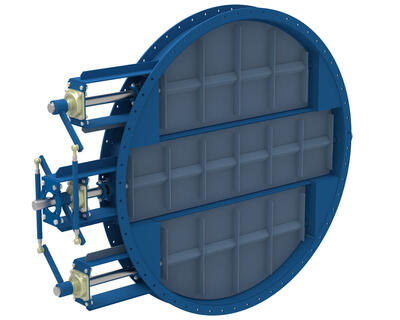

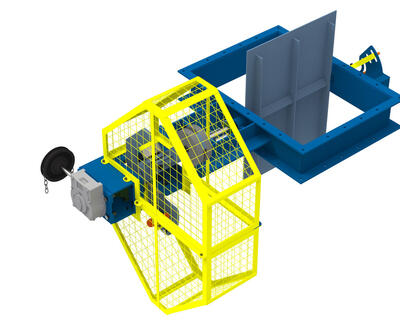

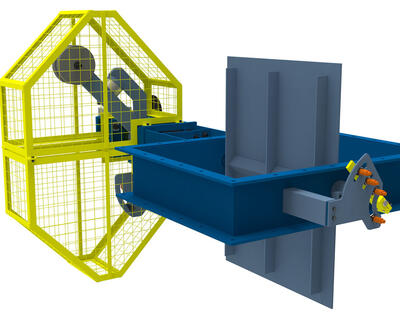

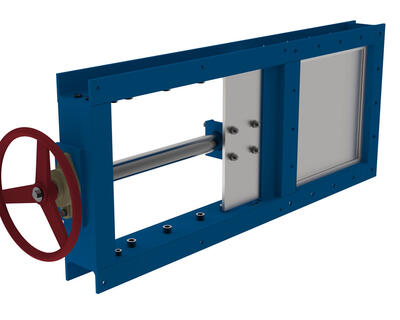

Variants

| Body: | round, rectangular or customer-specific constructions |

| Materials: | S235JRG (1.0038), P265GH (1.0425), 16Mo3 (1.5415), 13CrMo44 (1.7335), 1.4301, 1.4541, 1.4571, 1.4828 and other materials on request |

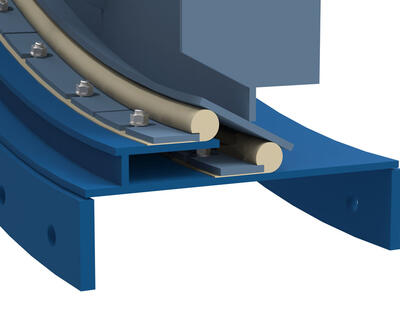

| Sealing: | soft sealing, metallic, sweeping seated, lamella sealing or with supply of sealing air |

| Operating pressure: | up to 500 mbar |

| Temperatures: | up to 650 °C, higher temperatures on request |

| Medium: | air, dust-contamined air, flue gas |

| Flanges and Face-to-face dimensions: | upon customer requirements or according to NOVAL standard |

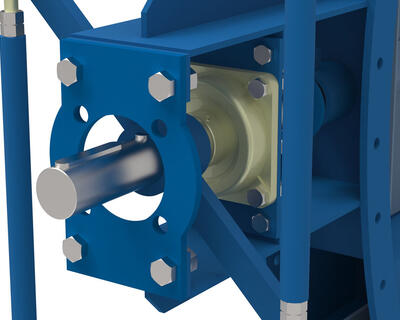

| Operation: | manual, electric, pneumatic with or without controller |

| Options: |

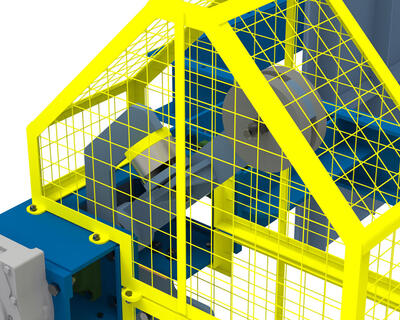

The dampers can be equipped with additional external position switches/sensors. Damper blades can be isolated. |

| Corrosion protection: |

upon customer requirements or according to NOVAL standard |