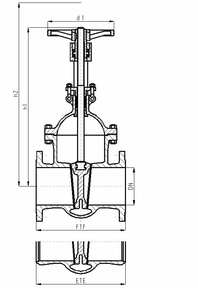

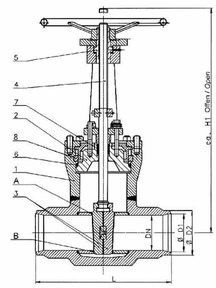

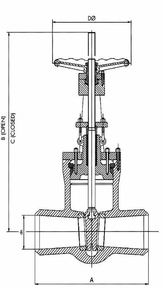

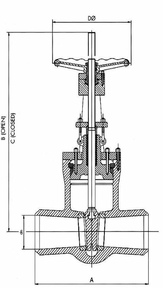

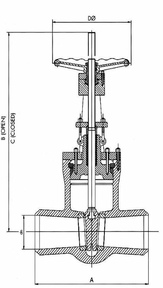

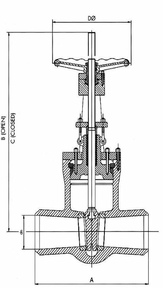

Gate Valves

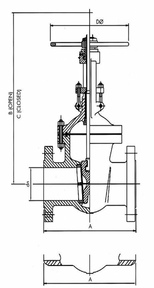

Gate valves are the most frequently used and sought-after valves for pipelines. They are constructed for OPEN-CLOSED positions and are not applicable for throttling or regulating purposes. In general, gate valves consist of a valve body and a bonnet, and inside there is a blocking member which moves perpendicularly to the direction of the flow. The usual materials to produce gate valves are steel and cast iron. Corrosion protection is reached through a dense metal or metal-ceramic coating in the form of powder or hard-facing on the surface of the valve.

Types of gate valves

Different gate valve types are implemented in various industry branches, as well as in the housing and utilities infrastructure.

A gate valve type is defined through its construction peculiarities and the shut-off member form.

Gate valves are preferred for gaseous and fluid media, and they are well-applied for high pressures. Depending on the shut-off member, there are parallel gate valves, wedge gate valves, gate valves with a rising or a non-rising stem.

Knife gate valves are mainly implemented for the media with high solid matter contents, especially given a low operating pressure. They are equipped with a shut-off plate which ensures a tight closure for the media containing solid matters, because it cuts into the solid matter similarly to a knife. In addition to that, those valves have an advantage of small stagnant zones which allows to avoid clogging.

Peculiarities of gate valves

Here are some of the special traits and advantages of gate valves:

- Very broad range of implementations

- High reliability and long operating life

- Simple constructive solution

- Short face-to-face dimension

- Small flow losses thanks to the full usage of the bore

- In most cases, bidirectional sealing

The most widely used kind of control for the gate valves is manual. If gate valves are implemented for a frequent switching or for safety functions, then they are controlled with electric, pneumatic or hydraulic actuators.

The possible connection types between the pipeline and the gate valve are flange, socket, thread and butt-weld ends.

We offer

A broad range of shut-off valves is presented in our catalogue; our valves are in accordance with the most important production norms.