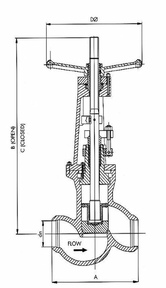

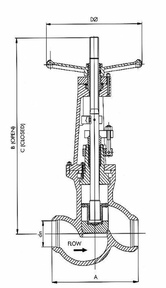

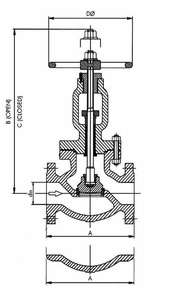

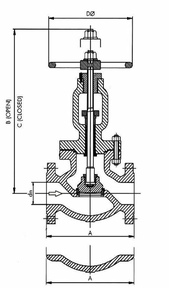

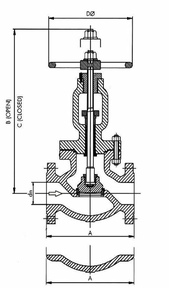

Globe Valves

Globe valves are the most wide-spread kind of shut-off valves for pipelines. The main purpose of these devices is a full or partial (with throttling or regulating function) shut-off of the working medium flow. The movable operating element of a globe valve is a stem.

Shut-off globe valves and regulating globe valves insure a normal function of technological systems and support the stability of their working parameters.

Advantages of globe valves

A globe valve has many pros, among others:

- Good tightness.

- Effective and simple construction.

- Uncomplicated maintenance and repair.

- Compact dimensions.

The choice of sealing

The construction of globe valves has a few peculiarities. For example, depending on the sealing materials, it is distinguished between:

- globe valves with stuffing box,

- globe valves with bellow.

At normal temperatures the stuffing box is a better choice of sealing material. During the work within large temperature differences the sealing must, however, be additionally protected; the effective options could be either special cooling ribs, or protective measures against frosting.

A bellow is flexible sealing. One side of the bellow is connected tightly to the valve body, while the other one is adjacent to the valve parts.

The bellow securely tightens the stem and the packing gland from the working medium. This is especially important for the work with high-temperature, explosive and toxic working media. The disadvantages of this technique are a shorter operating life and a complicated replacement of the bellow construction.

The choice of connection tightness

An important construction feature is the connection between the pipe and the valve:

- Flanged.

- With butt-weld ends.

The connection with a flange is applied most often. Butt-weld ends are mainly suitable for high-pressure pipelines and steam circuits. The main advantage of the welded construction is tightness. Its disadvantages are a constrained maintenance possibility and a higher price.

We offer both standard goods and special solutions made of many different materials.

You are welcome to make your inquiries for globe valves, throttle valves and regulating valves per e-mail or by phone.